The three-axis horizontal screen is installed horizontally. The screening machine uses three sets of vibrators as excitation sources, and the motion trajectory of any point on the screening box is a linear ellipse. The material moves in a linear ellipse on the screening surface.

Three-axis horizontal screen is suitable for dry and wet screening of coal, mining, and sand and gravel aggregates. It combines the advantages of circular vibrating screen that loose materials are not easily blocked, and linear vibrating screen that transports materials quickly and has a low center of gravity.

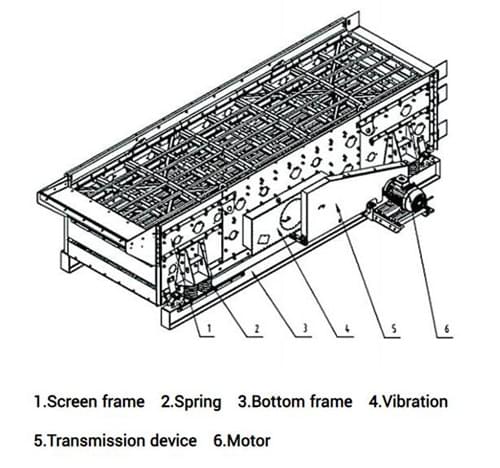

The three-axis horizontal screen is composed of screen frame, spring, bottom frame, exciter, transmission device, motor, screen mesh, etc

When the three-axis horizontal screen is working, the power is transmitted from the motor through a triangular belt to the driving shaft and gear vibrator of the exciter (with a speed ratio of 1), achieving the rotation of the three shafts at the same speed, generating excitation force. The exciter is connected to the screen box with high-strength bolts, resulting in elliptical motion.

The material moves in a high-speed elliptical motion on the screen surface, quickly layering, passing through the screen, and moving forward to complete the classification of the material.

| Model | Screen Width (mm) | Screen Length (mm) | Screen Area(㎡) | Screen layers | Screen Aperture (mm) | Input Size (mm) | Capacity (t/h) | Power (kw) | Excitation Force (KN) | Weight (kg) | Overall Size(mm) |

| 1848 | 1800 | 4800 | 8.64 | 2 | 5-50 | ≤100 | 50-400 | 22 | 35 | 5000 | 5900X3100X1700 |

| 1848 | 1800 | 4800 | 8.64 | 3 | 5-50 | ≤100 | 50-400 | 22 | 40 | 6000 | 5900X3100X2000 |

| 1860 | 1800 | 6000 | 10.8 | 2 | 5-50 | ≤100 | 50-400 | 22 | 40 | 6000 | 7100X3100X1700 |

| 1860 | 1800 | 6000 | 10.8 | 3 | 5-50 | ≤100 | 50-400 | 30 | 45 | 7000 | 7100X3100X2000 |

| 2060 | 2000 | 6000 | 12.6 | 2 | 5-50 | ≤100 | 50-600 | 30 | 50 | 8000 | 7100X3300X1700 |

| 2060 | 2000 | 6000 | 12.6 | 3 | 5-50 | ≤100 | 50-600 | 30 | 60 | 9000 | 7100X3300X2000 |

| 2460 | 2400 | 6000 | 14.4 | 2 | 5-50 | ≤100 | 100-700 | 30 | 60 | 9000 | 7100X3700X1800 |

| 2460 | 2400 | 6000 | 14.4 | 3 | 5-50 | ≤100 | 100-700 | 37 | 70 | 11000 | 7100X3800X2100 |

| 2760 | 2700 | 6000 | 16.2 | 2 | 5-50 | ≤100 | 100-800 | 37 | 70 | 11000 | 7100X4300X2000 |

| 2760 | 2700 | 6000 | 16.2 | 3 | 5-50 | ≤100 | 100-800 | 45 | 80 | 13000 | 7100X4400X2300 |

| 3060 | 3000 | 6000 | 18 | 2 | 5-50 | ≤100 | 100-900 | 55 | 80 | 13000 | 7100X4600X2200 |

| 3060 | 3000 | 6000 | 18 | 3 | 5-50 | ≤100 | 100-900 | 55 | 90 | 15000 | 7100X4700X2500 |

| 3090 | 3000 | 9000 | 27 | 2 | 5-50 | ≤100 | 100-1000 | 55 | 95 | 16000 | 10100X4700X2400 |

| 3090 | 3000 | 9000 | 27 | 3 | 5-50 | ≤100 | 100-1000 | 75 | 105 | 18000 | 10100X4700X2700 |