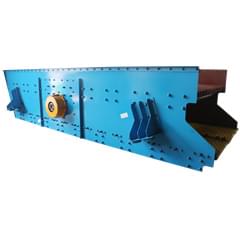

This Y series vibrating screen is vibrated by the circling motion. It is high efficient screen for filter materials into multiple grade according to the gravel size. For the compact structure and the convenient installation, it is the ideal screening device for prefilter of the feed materials before the primary crushing in the quarry site, it also can be used as separation and filtration solely.

This Y series vibrating screen is vibrated by the circling motion. It is high efficient screen for filter materials into multiple grade according to the gravel size. For the compact structure and the convenient installation, it is the ideal screening device for prefilter of the feed materials before the primary crushing in the quarry site, it also can be used as separation and filtration solely. The vibrating screen adopts cylinder type eccentric shaft vibrator and partial block to adjust the amplitude. The materiel sieve drip line is long and more sieving specifications. The circular vibrating screen can also be used for production classifying in quarry, mine, construction, electricity, chemical industry,etc.

1. The vibrating screen uses the motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force. 2. The materials make circular movement on the screen to realize sieving.

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Screen Area (m²) | Power (kw) | Overall Size (mm) |

| 2YK1548 | 0-200 | 0-160 | 1500*4800 | 7.2 | 11 | 5000*2900*2900 |

| 2YK1860 | 0-200 | 0-200 | 1800*6000 | 10.8 | 15 | 6200*3400*3500 |

| 3YK1860 | 0-300 | 0-200 | 1800*6000 | 10.8 | 22 | 6200*3400*4100 |

| 2YK2160 | 0-200 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*3500 |

| 3YK2160 | 0-300 | 0-250 | 2100*6000 | 12.6 | 22 | 6200*3700*4100 |

| 2YK2460 | 0-200 | 0-300 | 2400*6000 | 14.4 | 22*2 | 6200*4100*3800 |

| 3YK2460 | 0-300 | 0-300 | 2400*6000 | 14.4 | 30*2 | 6200*4100*4400 |

| 2YK2472 | 0-200 | 0-300 | 2400*7200 | 16.8 | 22*2 | 7400*4000*4000 |

| 3YK2472 | 0-300 | 0-300 | 2400*7200 | 16.8 | 30*2 | 7400*4100*4600 |

| 2YK3072 | 0-200 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4100 |

| 3YK3072 | 0-300 | 0-300 | 3000*7200 | 21.6 | 30*2 | 7400*4700*4700 |

| 3YK3672 | 0-300 | 0-350 | 3600*7200 | 25.92 | 37*2 | 7400*5400*4700 |